Bond Bug ZZR1400 Project |

The canopy originally had a single hydraulic piston to manually lift it which caused in a lot of cases to put a bow in the middle of the structure.

This has been removed and two new matched electric actuators run in parallel have been bought to install in the side wings.

They can be operated by a remote control fob and cannot lift unevenly if either is out of sync using a positioning controller.

Check out https://www.gapp.co.uk/ for all the different types and applications they cover.

Brilliant customer support also.

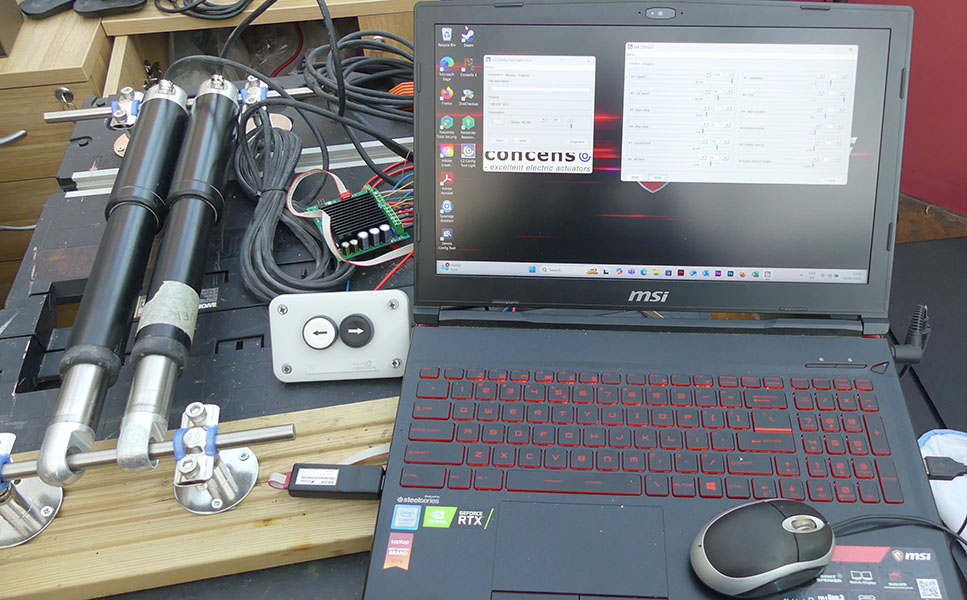

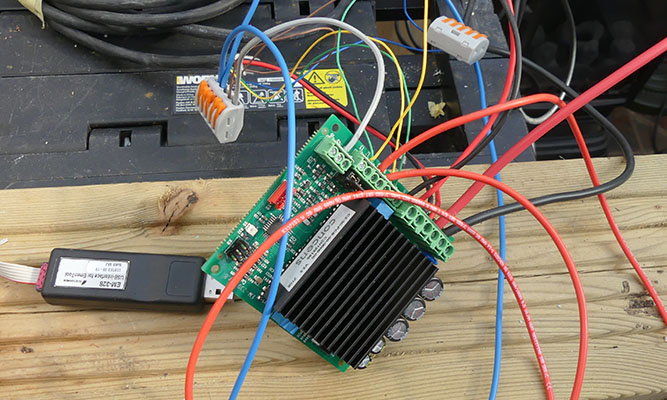

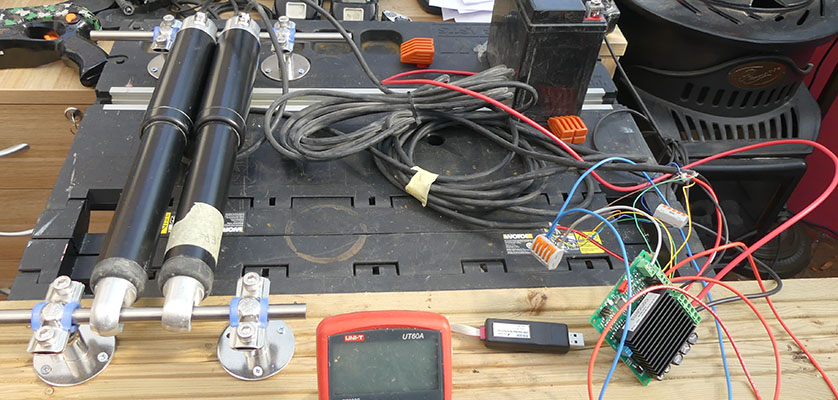

Used a laptop with a USB dongle attached to connect to the C2 controller -I then used the supplied software to program both linked actuators together to wokk in sync.

Ther are many clever perameters you can adjust like a slowed down soft close.

Both actuators now rise and fall together perfectly and cannot go out of sysnc when lifting the canopy.

Constructed Bench set up ready for syncing dual actuators with electronic control unit. The two units cannot go out of sync while lifting the Bug canopy.

Lots of useful videos below to change parameters.

the C2-30 is designed for operating two Concens

actuators in parallel. Synchronization is achieved by

adjusting actuator speed during operation.

Failure to synchronize will result in the actuators stopping,

this way possible mechanical stress and breakage can be

avoided. Additionally the C2-30 includes current limiter

and power stage temperature protection. The C2-30 has

adjustable start and stop ramps for smooth operation.

The C2-30 works in conjunction with actuators with hall

sensors only.

The basic control is done with Forward-, Backward-, and

Stop-commands, either in continuous mode or pulse mode.

Calibration input is for operating the system to its initial

position. This is done with low speed.

A wide range of parameters can be altered to suit to

different demands and applications.

The parameters are set by using the handy interface

C2-PROG or by using the C2-USB dongle and your

computer. Both must be connected to the red connector

on the PCA.

This datasheet is related to C2-30 firmware version 2.5

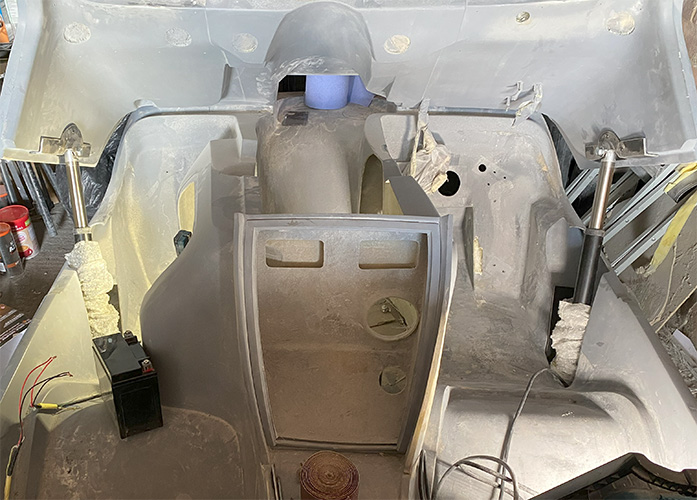

Double canopy lift actuators now fitting and working

2 - Custom made electric actuators and electronic control unit arrived today

Actuator A fitted

2nd actuator top canopy mount drilled and tapped

Actuator B

Actuator fitted and now lifts the canopy easily

2nd canopy actuator bracket mocked up for welding - note the fibre glass template used to get the tricky angles correct

Final canopy bracket for actuator

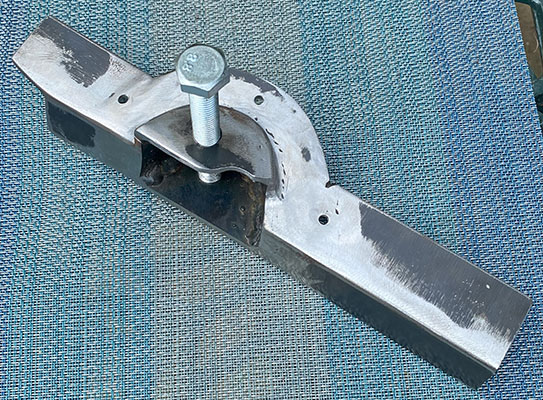

More top mount plate parts made

Top actuator curved section of mount formed

Mocking up top actuator mount into canopy using fibreglass proforma and 4mm thick steel sheet

Bottom actuator mount finished ready for welding

Actuator bottom bracket now mocked up in 4mm steel sheet. It is held together with filler ready to be welded

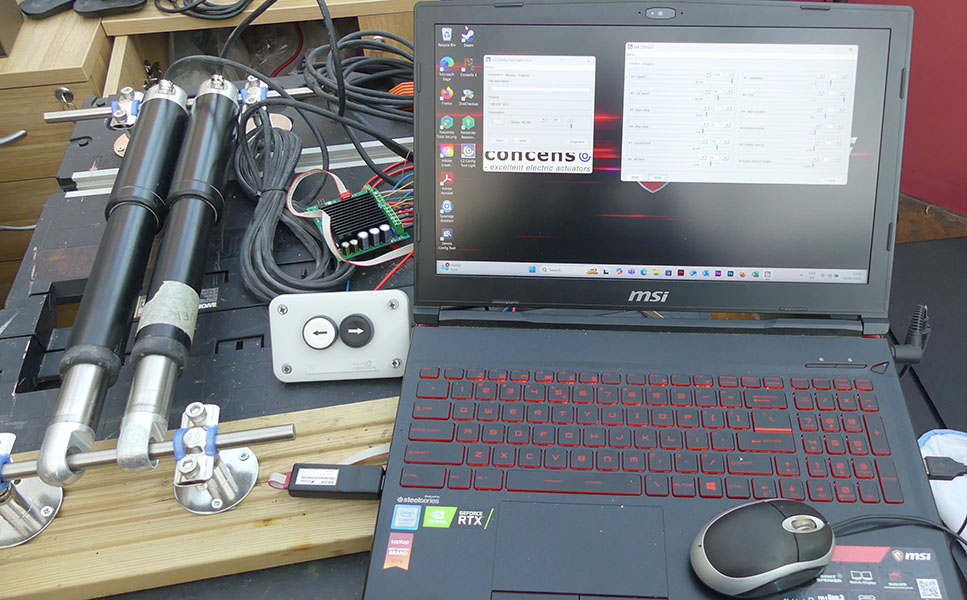

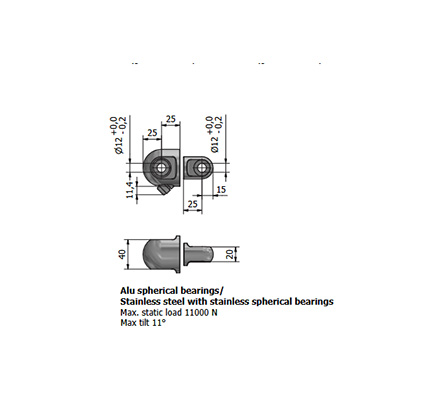

The Con 50 has been custom made for a 150 mm stroke. I ordered the black powdered coated body with stainless steel piston. It is IP66 rated so perfect against any moisture.

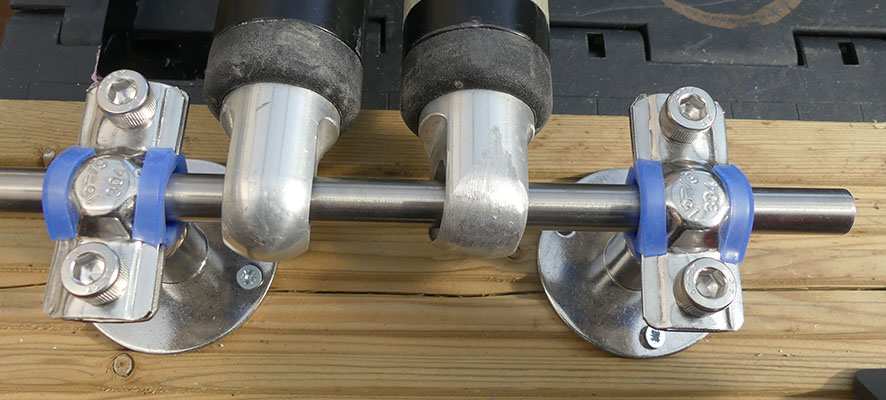

I had custom ball rotating mountings ends fitted to the actuators. I also now have the positioning controller that is programmable for all the actuator functions, feedback so both actuators can only rise and lower in sync.

It offers current limiting protection, working stroke, speed limiting etc.

As great safety feature the actuator locks when stopped and cannot fall back. It also secures the canopy when closed.

The con50 in line linear actuator from Concerns offers a sleek compact design, ideal where space if of a premium, powerful actuator offering up to 4500N, available in powdered coated

carbon steel or ASIS316 stainless steel, duty rating of 10%, high IP rating, options include clevis ends and hall effect sensor feedback.

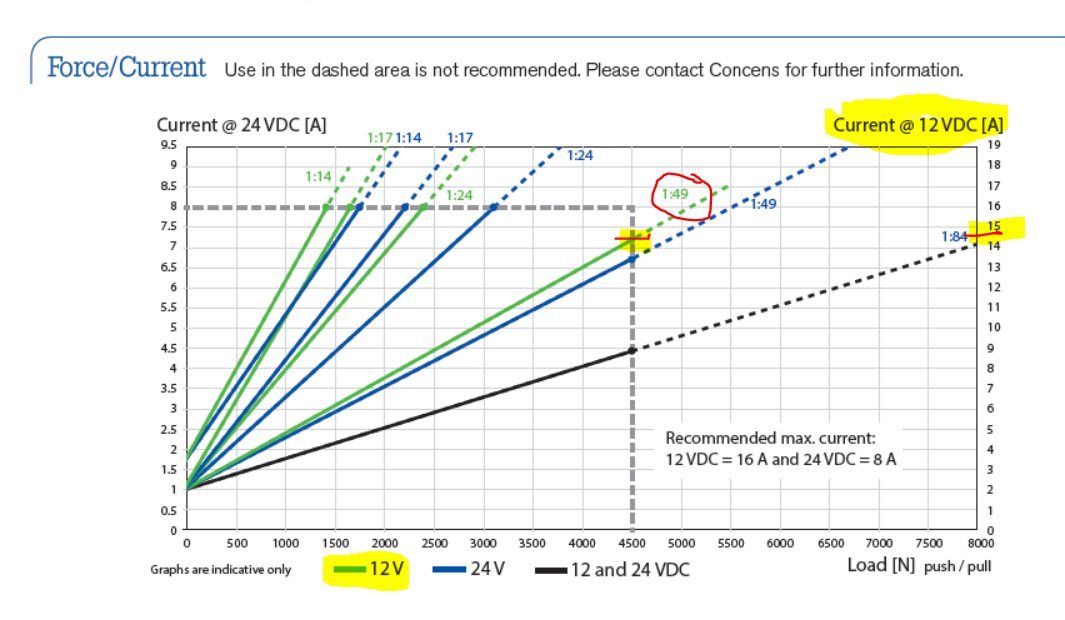

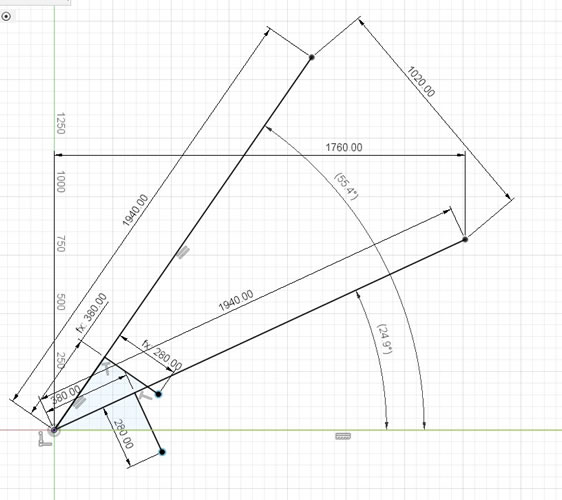

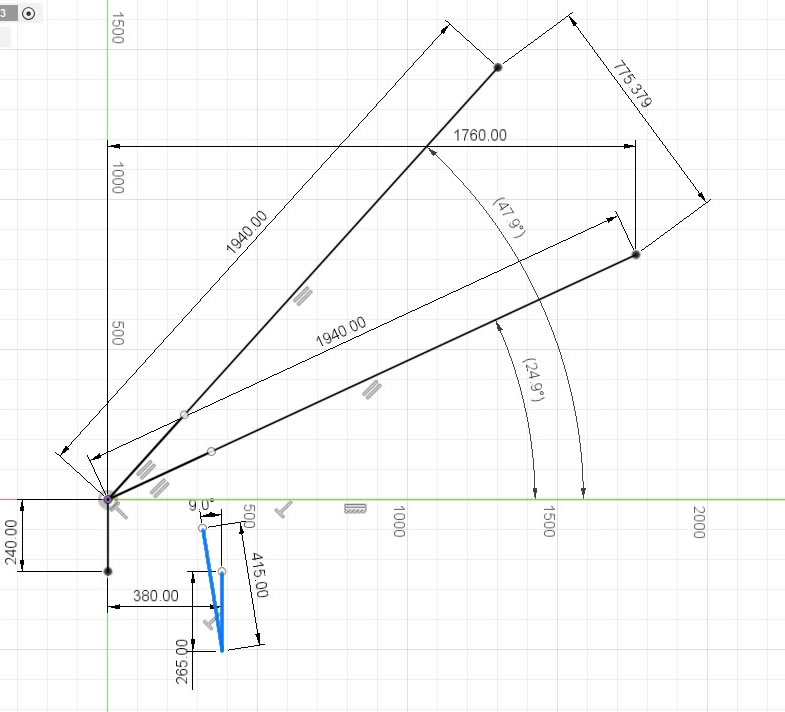

Revised canopy positions and loadings.

Now 2 x special actuators have been build with 150mm lift and a closed length of 425mm. I have moved the actuators closer to the pivot point which give the two 4500Nm actuators

at a 30 degree lean. The total needed is 6000 Nm which gives it a good safety overhead

Bond Bug working drawing for actuator loadings, size and fitment have been revised.

The canopy weights 174 kg, 2 side doors weigh 8kg the pair , glass windscreen 7.1 kg. Total 189.1 kg.

Lifting the load vertically is the best scenario in terms of loading.

Lifting at an angle increases the effective loading that the actuator will experience (by a factor of 1 divided by Cosine of the angle)

For example if the angle is an extra 20 degrees from vertical, then load the actuator will see will increase be 6.4%

And 30 degrees would equate to 15.4% more loading, etc.,