Bond Bug ZZR1400 Project |

Fuel and cooling

New fuel filler tube and neck constructed out of fibreglass

Flap is a Bentley Continental to be recessed into the body

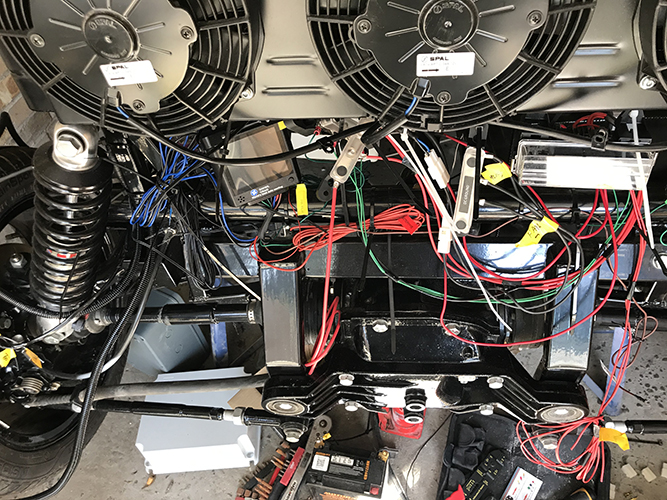

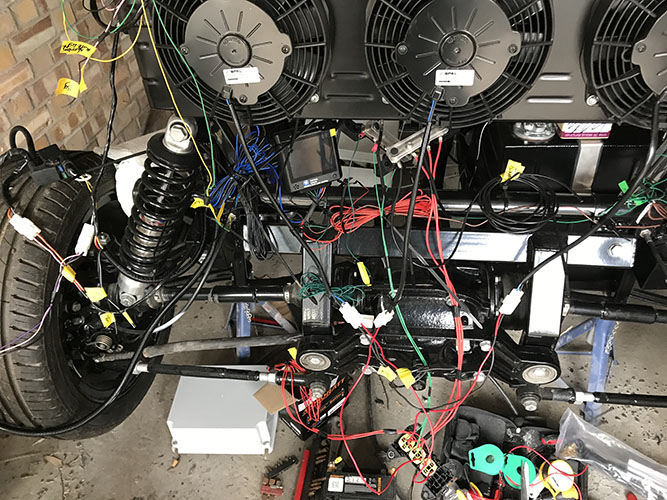

The new ZZR 1400 engine requires a lot of extra cooling so a triple radiator and fan units have been build and installed to fit into the existing boot.

The unit remains fixed to the main frame so that the body can be lifted off without their removal.

Fan wiring finished - got to mount final positions and tidy up

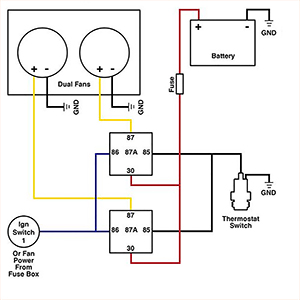

Rear fans and controller wired in via 40 amp diode relays

A new in line variable electric pump (EWP 80) circulates the coolant. The existing impeller and shaft have been removed from inside the engine to give freer flow.

The main piping used is hard aluminium.

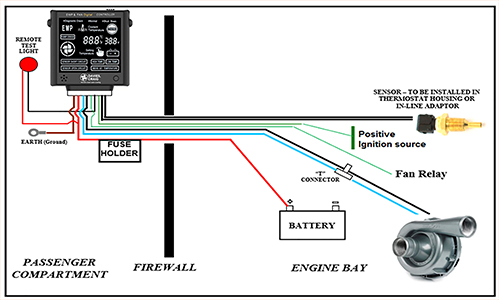

Added digital fan/pump controller

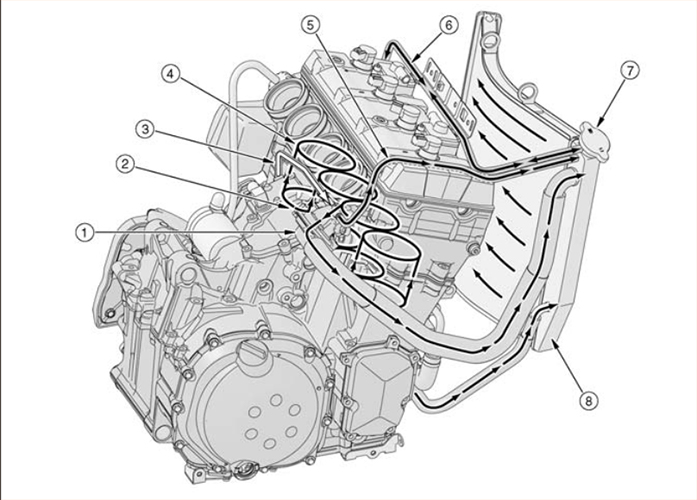

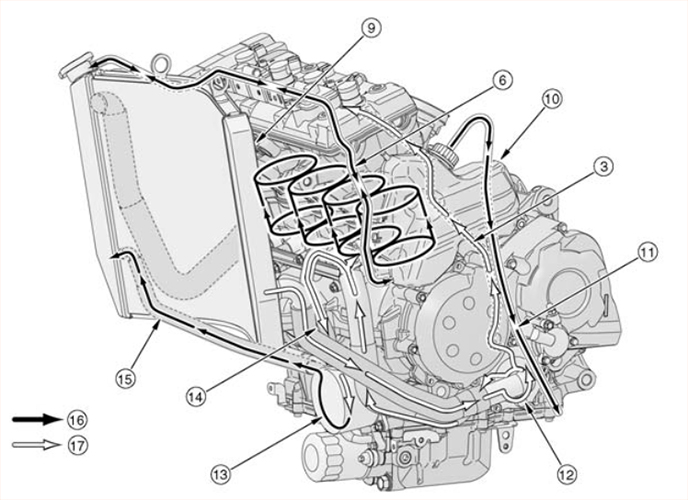

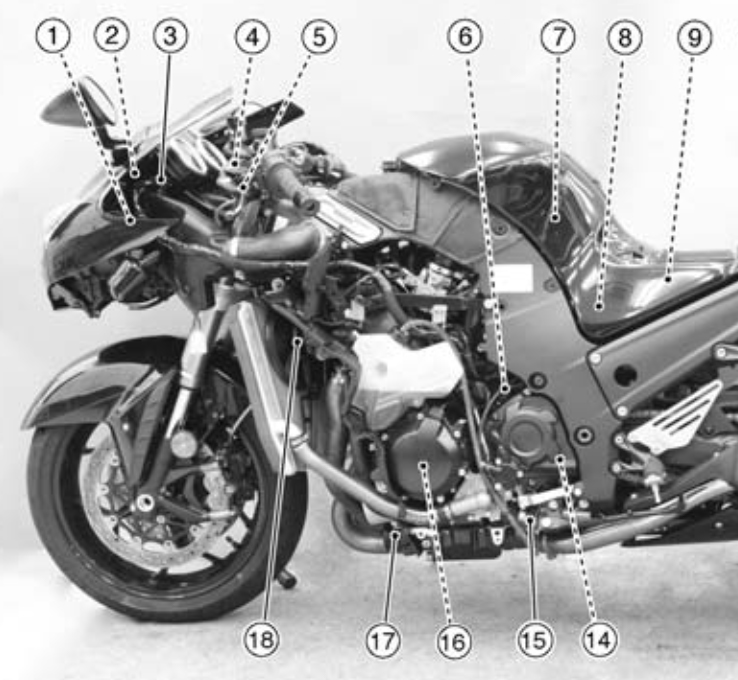

1. Thermostat Housing 2. Cylinder Jacket 3. Air Bleeder Hose for Water Pump 4. Cylinder Head Jacket

5. Air Bleeder Hose for Thermostat Housing 6. Reserve Tank Hose 7. Radiator Cap

8. Radiator 9. Radiator Fan 10. Reserve Tank 11. Reserve Tank Overflow Hose

12. Water Pump 13. Oil Cooler 14. Intake Hose 15. Outlet Hose 16. Hot Coolant 17. Cold Coolant

The thermostat is a wax pellet type which opens or closes with coolant temperature changes. The thermostat continuously changes its valve opening to keep the coolant temperature at

the proper level.When coolant temperature is less than 55°C (131°F), the thermostat closes so that the coolant flowis restricted through the air bleeder hole,

causing the engine to warm up more quickly. When coolanttemperature is more than 58∼62°C (136∼144°F), the thermostat opens and the coolant flows.

When the coolant temperature goes up beyond 95°C (203°F), the radiator fan relay conducts to op-erate the radiator fan.

The radiator fan draws air through the radiator core when there is not sufficientair flow such as at low speeds.

This increases up the cooling action of the radiator. When the coolanttemperature is below 90°C (194°F), the fan relay opens and the radiator fan stops

Header tank location on the engine

This latest version of the Davies Craig LCD EWP and fan digital controller provides complete cooling system control to keep your engine running at an optimum temperature.

It can manage the speed of a Davies Craig electric water pump (EWP) and control the switching of an electric cooling fan

Proalloy designed and built all the units and plumbed it in. They also designed and built the new custom foamed filled alloy fuel tank.

I supplied an existing Kawasaki fuel pump to be fitted into the fuel tank.

PRO Alloy made a U Tube vid of their work

https://www.youtube.com/watch?v=t0VGS2-_bPE

Triple fan unit being constructed

http://www.proalloy.co.uk/cgi-bin/sitewise.pl?act=det&pt=52_1608_1991_2005&p=2006&id=proalloy

Final fitting after powder coating

Fuel tank sizing and new support plate

Tank sitting in support tray- tank is filled with foam to prevent explosion

.jpg)

Triple fan wiring circuit