Bond Bug ZZR1400 Project |

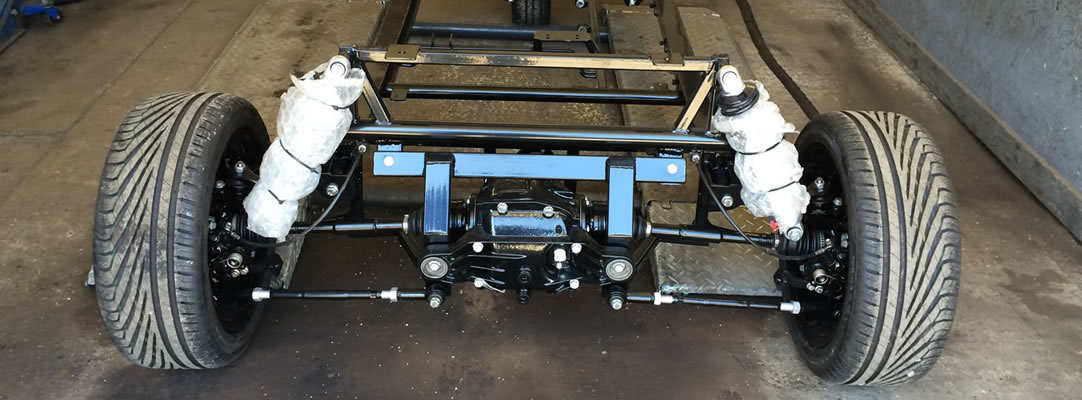

All the items built, frame, hubs, diff etc were built/assembled and then stripped down back to their casings. All metal work has been bead blasted then powder coated before reassembly.

I used a company in Maldon Essex for all this work

https://ctc-powder-coating.co.uk/

Note: When powder coating an item such as a diff, because it is baked after coating, it must be stripped back to its castings. Oil will seep out of the joints and ruin the finish if it is baked in one piece.

Also all rubber bearings and seals will be potentially damaged during the baking process so they must be removed first.