Bond Bug ZZR1400 Project |

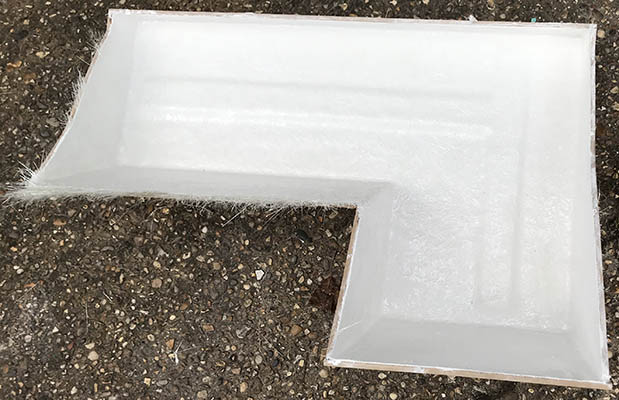

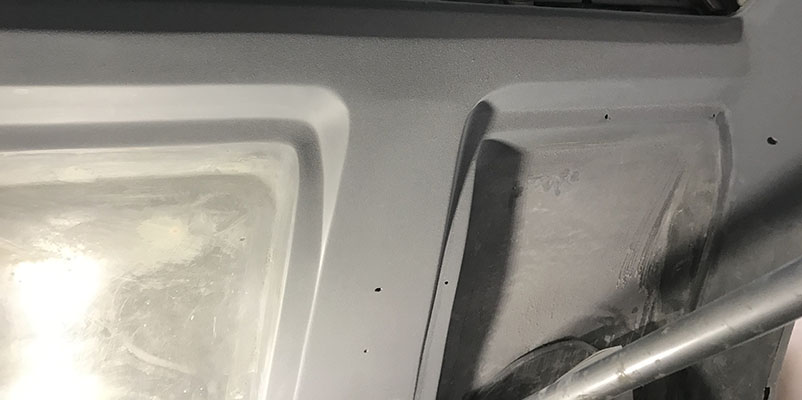

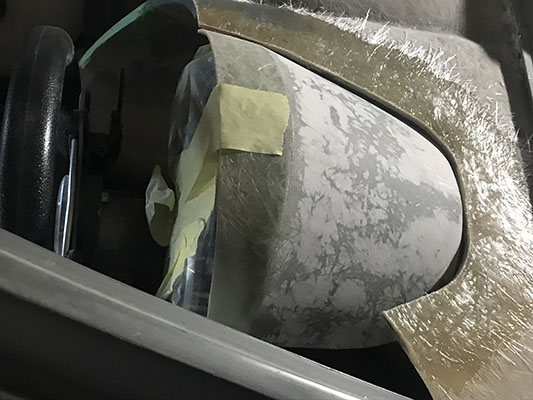

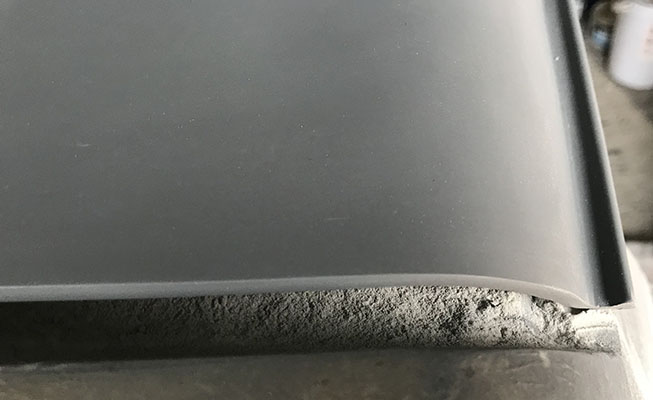

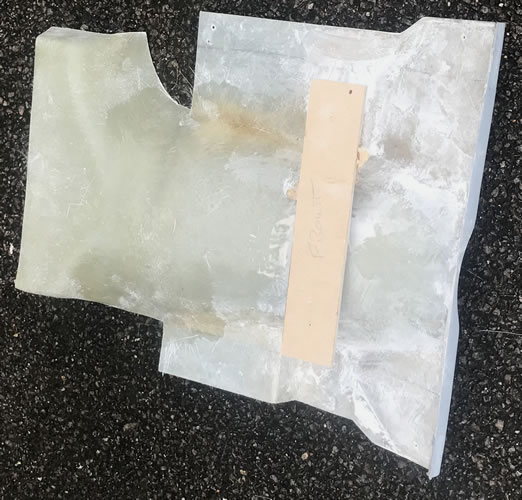

The existing body work is all fibreglass with steel inserts for fixings. All the steel inserts for the canopy hinges etc have rusted and 'blown' with age making the fibre glass bulge.

I have had stainless steel plates made up to replace all of them. Every existing hole for rear lights, gauges, stereo, speakers etc have been filled in with fibre glass to give it a blank canvas for upgrades.

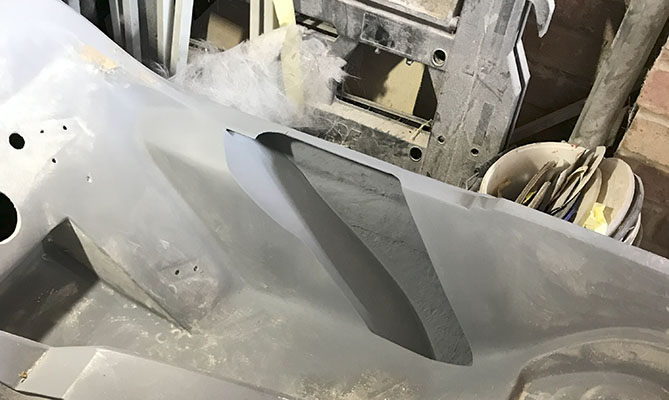

Huge chunks had to cut from the existing shell to accommodate the larger engine.

Wheel arches had to be cut out to suit the change from 10 inch to 15 inch rear wheels and the wider stance on the new axle.

The gear knob and hand brake lever have been taken out as they are now electronically operated. The only lever in the cabin will be the Quaife reversing gear box.

Huge amounts more work to be done yet.

GIDERWEL Smart App Controlled LED Fiber Optic Lights Kit,200pcs 2m 0.75mm Optical Fiber Star Ceiling Lights with 7W Smart Light

Fibre optic kit for head lining in the Bug

The roof lining is having the 200 fibre glass lights fitted into it like the Rolls Royce has.

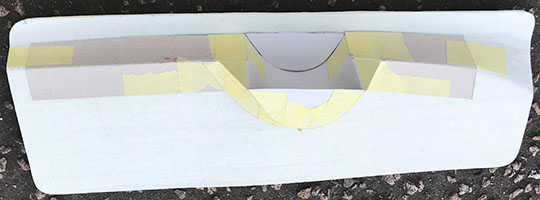

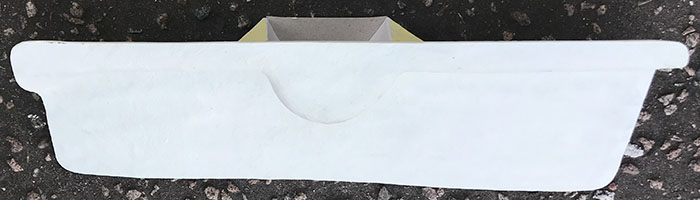

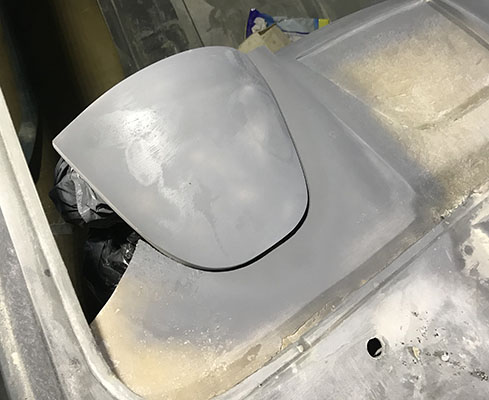

The roof lining for the ceiling insert panel is moulded in fibre glass. This will be drilled and covered in leather then pop fastened to the canopy.

The bulge in the canopy frame (bottom left) is moulded to fit over the light unit and will be have a fine mesh inset to allow for venting of the heat generated.

Ceiling panel/head lining almost ready to go to the leather trimmers after 200 random holes are drilled for fibre optic strands.

Trimming of body work bottom panels

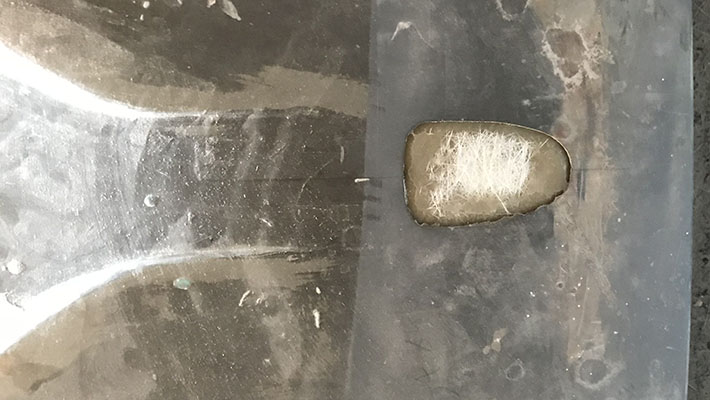

Reversing Gearbox lever cut out glassed back in

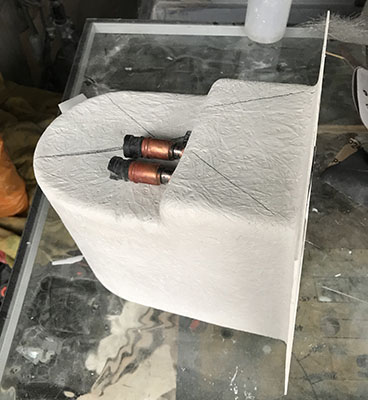

Speaker tweeters being mounded into canopy upright post covers

Canopy upright post covers - these are being covered in leather

Both side speakers housings being moulded in

Side speaker mount moulding taking shape

New side speaker mountings being moulded into body side using 18mm plywood

New driver seat panel insert to make new trap door for amplifier housing box

New passenger seat panel insert to make new trap door for ECU housing box

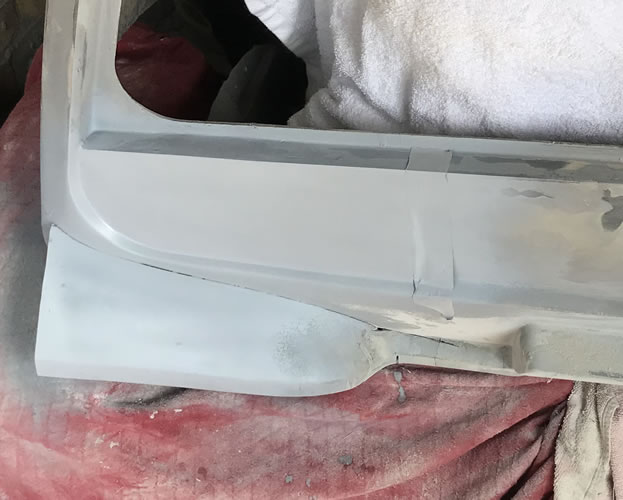

Detailing of sides

New side mould made to repair skirt

Test seat dials and flappy paddles fitted

Rubber mounted the test seat

Test fitting of pedal box

New seating - really strong tang added to secure seating unit to frame for testing

New seat losely laid in position

New seat made for road testing on new frame and engine

New fibre glass drivers seat and pedal box under construction. This will removed from the body and transferred to the engine and new frame set up so it can be tested like a go kart without the body being on.

I need to do serious testing of the overall handling, damper settings, brake balancing, paddle shift steering wheel, quickshifter etc prior to the final body going back on.

Airvent side surround moulded in foam ready for fibregalssing

Modded Bentley air vent on dashboard

Right front dash speaker fitted and Bentley air vent cut to suit

Internal canopy actuator bottom support brackets mocked up in fibreglass. These will now be copied in 4mm thick steel plate with a welded construction.

The finished metal bracket will be bolted to the already reinforced main body. The new metal support bracket will have a welded captured nut to support the actuator pivot bolt.

Canopy scoop inner detailing

Actuator mount moulds to make fabricated metal inserts and mounting plates - note the tricky curved shapes

Canopy actuator mounts

Actuator internal body side mount construction

2nd bottom canopy actuator mount finished

Super strong canopy now - filled with expanding foam from top to bottom

Two part liquid foam used with a plastic icing cake bag

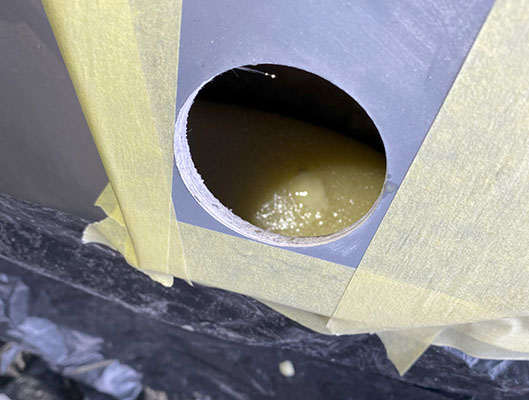

Access holes drilled into underside of canopy for foam filling.

Inner actuator boxing being glassed

Massively strong actuator bottom mount

New dual canopy lifting actuators supports being fibre glassed into place. Inner super strng box being formed inside the wing for the metal mounting pivots.

Magnetic Canopy lock plate fitted to heavily reinforced original lock position - this has to be mega strong to take the pull of the magnetic lock

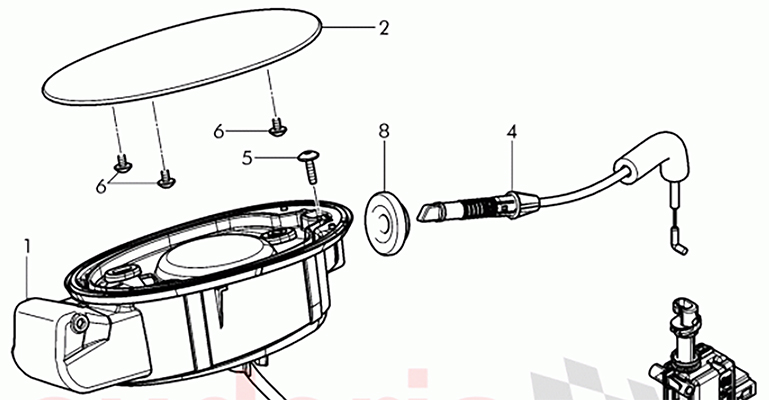

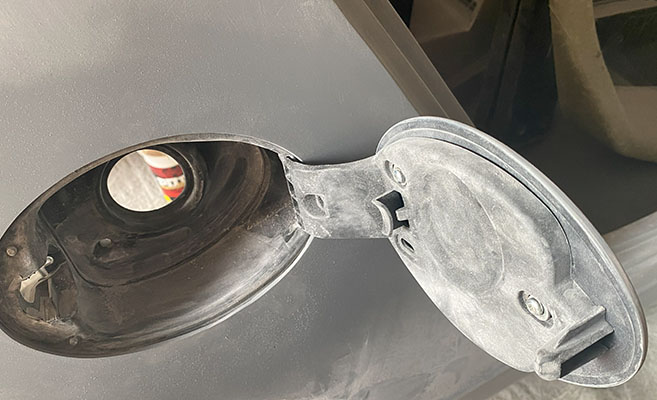

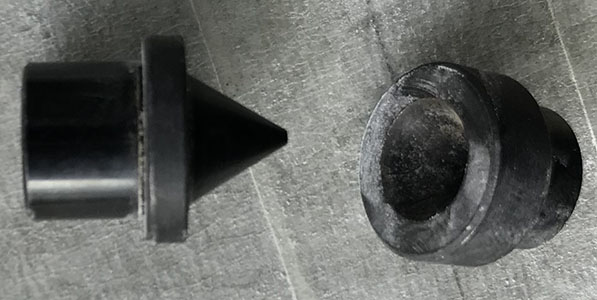

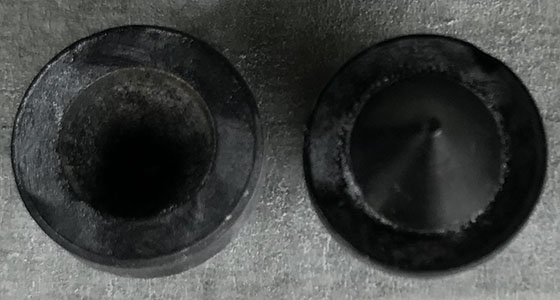

Electric fuel flap operator cable and gromet arrived

Bentley fuel flap with custom made neck and jewel cap

Inner mount now fitted - big head fittings use

Big head fittings fibre glassed in for mounts

New fuel filler inner mount

Bentley Continental flush fuel filler door fitted

More detailing work

Side detailing finished- fuel hole finished

Flattening out side panel for detailing and fuel filler hole now fibre glassed in

More side detailing work - grinding out star cracks

More edge detailing

Detailing of rear body edges, new boot floor ready to go in

New front indicator recesses fibre galssed in

Swage lines detailed

Front spoiler detailed

Inner air scoop and indicators fibre glassed in

Parcel shelf now detailed

Bug out ready to flipped onto its side

Headlight cowellings detailed

Front indicators and air scoops fitted

New air scoop now moulded into the spoiler - new indicator recessed

Slowly getting there with the mods

Two new fresh air intakes remade in fibreglass - fitted into front spoiler with ducting for fresh air intake into cabin

Front indicator lenses being recessed into front spoiler - fibre glassed box being made

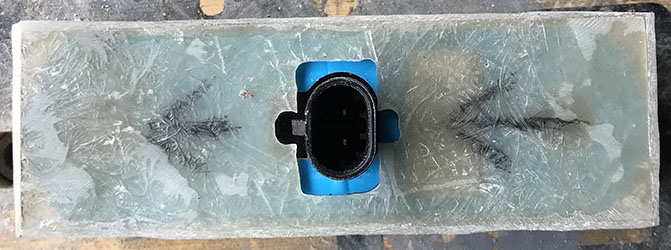

Light pods moulded in

Four new light pods finished

Rear light pods being constructed

Engine side flaps finished - Using DZUS fasteners to secure panels

Detailing head light and bonnet

Detailed central console

Steering column recess finished

Engine passenger side access panel finished

Engine driver side access panel finished

Engine side cover recess formed- Using DZUS fasteners to secure panels

Engine side covers - using DZUS fasteners to secure.

New engine side access covers cut

Heater box finished

Compact hot water fed heater- triple speed fan

Max air flow 170m3/hour

New fibre glass heater box under construction

Bentley badge bonnet fitting completed

Headlamps repaired and detailed

Interior detailing

Front spoiler and light fittings repaired and strengthening

Body side skirts repaired and reinforced

Sub woofer hole and speaker box fitted behind passenger seat finished - sub speaker loosely placed into hole

Correct cubic feet size for sub woofer box calculated for the tricky final shape

Original side speakers holes filled in

New sub woofer box now fibre glassed into place behind passenger seat

Under body work repairs and body edge strengthening

Bond badge mounting support completed

Under body strengthening and centre console/air con duct fitted

New sub woofer box ready for fiberglassing to boot area - excess to get the correct cubic area for the 10 inch sub woofer trimmed off - Note the thickness of the sub woofer box

Fibre glassing sub woofer box - added strengthening ribs

Sub woofer speaker mounting recessed into back of passenger seat. Seat backs are stiffened with 3 layers of fibre glass.

New MDF sub woofer box - correct cubic meter size for sub - ready for fibreglassing to make it more rigid - sub woofer speaker goes in recessed to the back of the passenger seat

Spoiler now moulded to body work

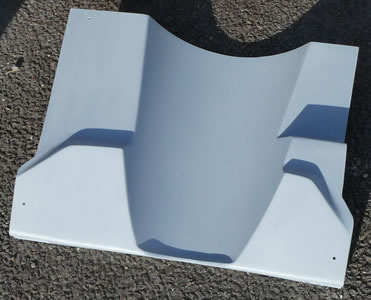

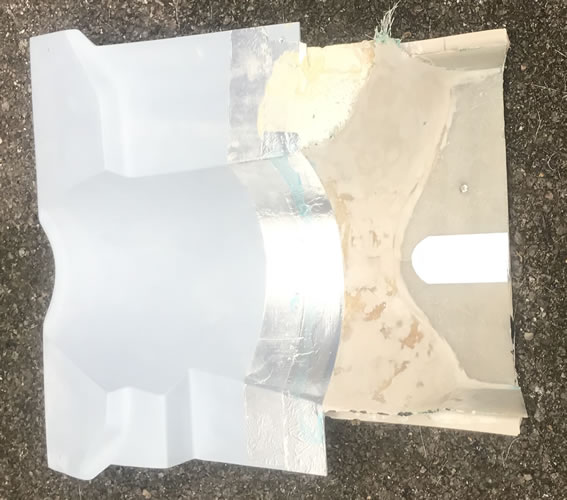

Finished spoiler out of the mould - ready to attach to Bug

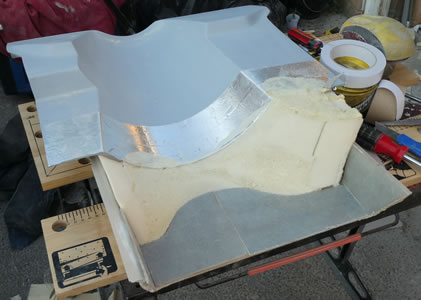

Spoiler mould made

Spoiler mock up ready for moulding

New rear spoiler being shaped ready for a mould to be taken

Previous repairs re- fibre glassed

Underbody modifications - new centre console with no manual handbrake or seat belt fixings

Bonnet cut out made for Bond badge - under bonnet has been stiffened to prevent flexing and recess for badge - previous repair cracks properly fibre glassed in

Engine bay mods and centre console

Canopy locator plug detailed into dash

Drivers engine side cover fibre glassed in

New pedal box fibre glassed in place

Passenger and driver side engine inner cover being fibre glassed in place

Body off the frame and fibreglassing all the new elements together

Mocking up reversing gear lever location in fibre glass

Hole filling and detailing

Canopy locator lug fitted - Under canopy finished

New pedal box fibre glassed in

Canopy locating lug mount finished - canopy rubber engine seal tested OK

Inner canopy locating lug fitted

Inner dash finished

Added double sandwiched locator plate - top plate will be fitted to canopy

Locating lugs being fitted into central dash board unit and canopy so they mesh exactly when canopy is closed.

Inner canopy moulding

Inner canopy

New Air duct moulded inlet customised to fit the Bentley dashboard vents

Air intake rear ducts now moulded

Removable side engine covers being mocked up

Engine passenger side cover extended to allow for rubber seal strip - Notched to mirror canopy closure profile

New central dash back plate - raised ring to accomodate alternator nut removal

Adding engine side cover top ready to take sealing rubber

Side dash now moulded around steering column support - removable engine side panel

Dashboard fibre glassed inner

Bentley Centre console now mocked up - lip added to dial cowling

Dial pod now loosly fitted

Both dash side wings now joined to centre console

Dash radius wing moulded

Bentley central grill now recessed into dash - dial cowling now loosly placed into position

Centre console section now joined with bendy ply and fibre glas - Kawasaki gauge unit now cut out of the top

Kawasaki dial cover mocked up in card board

New dash top panels being formed in bendy plywood and fibreglass. Bentley top air grill being inserted.

Mocking up dial cowling in card board

Body strapped to garage beams so it can be raised and lowered to trim body work and to get clearance around the 170amp external alternator

Mocking up dash board top in card board. The top dash is attached to the canopy and lifts up with it. Engine cover is split to allow access to engine.

Mocking up right hand side of console in foam

Centre console with now modified Bentley rear air intakes. The Bentley air ducts connect to a custom heater unit. The top of the Bentley console has another air duct grill to be modified from picture.

Bentley upper dash

Console backing

Console centre framework

Mocking up engine surround and dash in foam then fibre glass

Positioning new steering column ready to make up its fixings in relation to centre console.

Left hand side engine casing now made in fibreglass

Roof lock filled in and reliants bad filling on canopy top detailed.

All drainage channel on side of canopy fixed

Mocking up Bentley centre console fibreglass recess mount

New canopy side door hinge mounting plates finished

Working on replacing existing canopy latch fitting to covert to electro- magnetic catch. Lock now boxed in.

Detail work on canopy edges continues

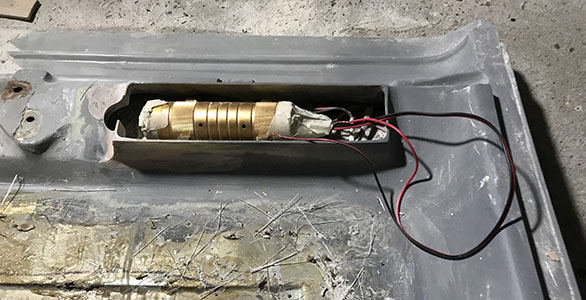

New canopy wiring for electronic rear view mirror and fibre optic ceiling lights being routed to hide them. Old side metal tubes cut out and new tubes and hinge mounting plates glasses in.

Added a 5th cable for conversion to two speed wiper motor.

Rusty Canopy side tubes and hinge mounting plates cut out and replaced with new metal and re-fibre glassed back in

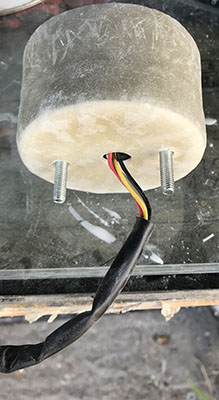

Fibre optic light unit recessed into canopy and secured by using Terry clips for easy removal. The hole is a lot larger than the unit and will be vented to allow for heat generated to escape.

The fibre optic light unit is only 7W but measuring its temperature output when fully lit it measured 33C so it needs this extra ventilation.

New 15mm rod inserts now fibre glassed into canopy side.

Existing wheel arches now cut off and foam moulding used to produce the template to take a fibre glass mould.

The old arches are the correct radius of the new wheels.

Tooling Gelcoat applied ready to be fibreglassed to produce mould

Arch mould preparation

Arch mould proforma and mould ready for final fibre glassing

Formed arch out of the mould

Finished light original holes blocked in

Left rear arch cut off ready for new mould production - foam being used to make new wider arches, the shape nearly ready to take mould

Left wheel arch finish ready to take mould

New right arch tacked on ready to joined to body

Left wheel arch mould and finished item

Left wheel arch to use to make mould

Original lighting holes

Number plate and lights detailed

Body work and canopy hinge mounting steel plates corroded and cut out. New stainless steel insets re-fibre glassed.

New aluminum hinge positioned in new stainless steel inserts

Canopy - new stainless steel hinge mounting plates fitted - new aluminum hinges fitted

New canopy hinges fitted- fettling needed to adjust shut lines.

Spoiler ready for new indicator lights and number plate

Over time both of the canopy sides had bowed out and are no longer flush with the bodywork.

Thin slices of fibre glass were cut out each side of the canopy to pull in the sides. The slots were re-fibre glassed to set them in new positions perfectly.

The canopy sides and body work are now perfectly flush.

Finishing off the canopy bottom

Starting the scoop construction on the canopy

Modeled central air-box cover scoop in fibre glass

Inner canopy scoop

Inner canopy scoop formed to clear air box

Canopy inner scoop loosely fitted

Finished first part of inner scoop moulding

2nd part of inner scoop being moulded in foam

2nd half of air scoop mould made.

2nd part of air scoop joined

Nearly finished air intake

This flow directs fresh cold air directly from outside into carburetter air box to improve perforamance. Almost ram air.

Clear fibre glass sheet made up to add more more trim to internal scoop

More inner scoop being shaping to accomodate the canopy rubber seal location

New outer scoop template mocked up using MDF

External canopy scoop mould made and internal duct offered up for sizing and fit.

Getting scoop out of its mould

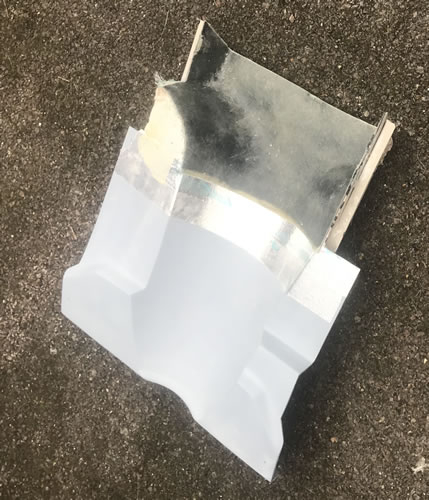

Scoop out of the mould ready for trimming - this is super strong to keep canopy stiff

Finished scoop being glassed in to its final position - inner scoop fitted temporarily

New scoop being glassed in place

Scoop edges blended to the canopy

Outer scoop radius added to match altered body inner radius - this allows for a body rubber sealant strip to be fitted to seal cabin

Spoiler now bonded to canopy top

Additional moulding to body air inlet

Test body seal rubber in place- using a special D shaped rubber profile that forms a great water tight seal between body and canopy.

Sponge D-profile 21x15mm with adhesive black

Shaping other side of the body air intake to suit new seal

Inner canopy moulding temporarily fitted

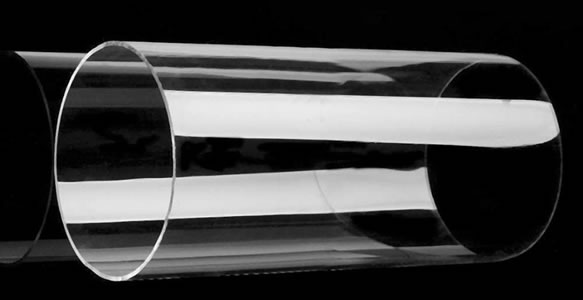

100mm dia OD pipe being used as a proforma for air box extension into scoop

Inner scoop loosely in place - not removing the original scoop cross member until new central canopy is reinforced.

New reinforcing canopy strip and window edge made

Nice mega strong fibre glass cross member and window edge formed

Internal canopy scoop laid in loosely

Body prepping- Roof shows Reliant's bad filler from the factory to a dip in the roof

Detailing work

Original body work chopped out ready for new mouldings

Original body work chopped out ready for new mouldings

Original body work chopped out ready for new mouldings

Serious soda blasting kit used

Under body has been soda blasted to remove 40 years of grime and flaking paint

Boot badge - higher or lower ?

Custom made new badge backing rubber to straighten out concave badge mounting to flat boot lid.

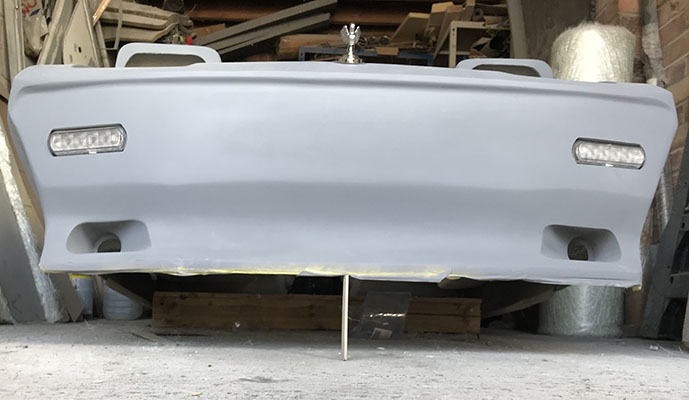

Custom made rear boot in steel with mesh insert to allow triple fan unit to expel air. Crome hinges and Bentley badge added. Boot lid is held in place with remote fob operated magnetic lock.

I have included 'door poppers' so the boot releases and the Classic Mini door straps.