| Bond Bug ZZR1400 Project |

My custom Bug back in 1984 at the Burford Micro Car Rally

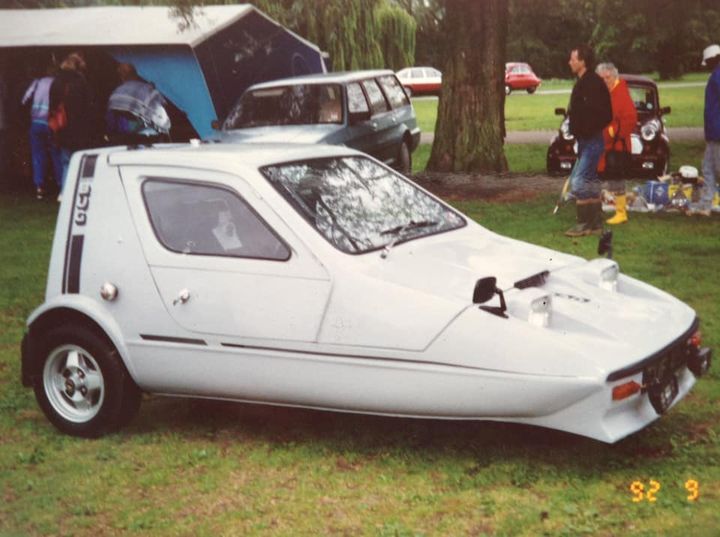

Later picture of my Bug in 1992, now sprayed light grey with added Webster solid doors and spot lights.

I have owned TUF415J since 1983 when I bought her for a princely sum of £100 back then. It was in very poor shape and I spent the whole of the next year completely restoring it from scratch.

The original engine was a 700cc Reliant alloy engine developing 28bhp. I replaced it with an over-bored 850cc Reliant engine with as many performance upgrades I could do. I had a 'Mike the Pipe' extractor manifold and exhaust made,

engine head was skimmed and gas flowed, electronic ignition, twin 28/36 weber carbs fitted etc which after a rolling road test developed 60 bhp. In 1984 I attended the Burford Micro Car rally and won 1st price for concours.

I used the 'suped' up Bug as my daily mode of transport for many years until my gearbox failed and I was in the process of converting an 850 cable operated box to the Bug hydraulic type. Kids came along and the Bug never got put back on the road.

Now I have more time on my hands and more cash to spend I decided to completely restore the Bug but this time bringing it up to more modern performance and getting experts to make most the bits.

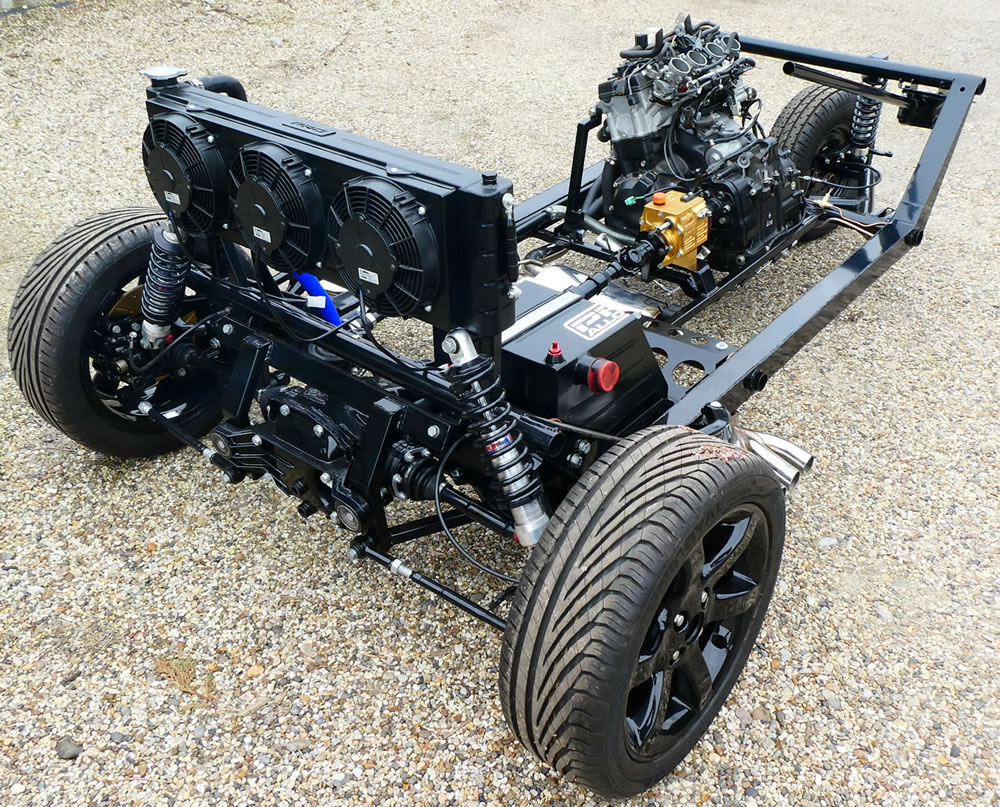

The result is a 200bhp Kawasaki ZZR1400 engined beast, into a Quaife reversing gearbox, into a BMW 318i limited slip diff with MGTF independent rear suspension.I have added lots of specialist electronic bits, triple fan cooling with digital controlled water pump.

Baffled sump, foam filled fuel tank, electric actuator canopy lift etc.

Might be the final colour of the Bug - Bentley paint work

Updated 23rd Sept 2025

New ceiling panel/head lining made for fibre optic lightsBody work

Reversing gearbox lever cut out glasses inBody work

Leather trimming type chosen, test pieces tested on A pillars.

Moulding in Canopy side upright post covers, including speaker tweeter positionsBody work

Both side speaker housings completeBody work

Side speaker moulding detailing finished Body work

New side speaker mountings being moulded into body using 18mm plywoodBody work

Under driver and passenger seat ECU and Amplifier box housings startedBody work

Side body detailingBody work

Programming of actuators now completedActuator canopy lift

Constructed Bench set up and wiring ready for syncing dual actuators Actuator canopy lift

New side mould made to repair side skirtBody work

Java download completed ready for dual actuator syncing using the C2-30 controllerActuator canopy lift

2nd canopy actuator test sucessfulActuator canopy lift

2nd canopy acuator mount completedActuator canopy lift

Test seat dials and flappy paddles fittedBody work

Test seat rubber mountedBody work

Top actuator mount, drilled, tapped and now boltedActuator canopy lift

Test fitting of pedal box to seat unitBody work

Actuators loosely fitted to brackets and it works perfectly at lifting canopyActuator canopy lift

Seating tang addedBody work

Top and bottom actuator brackets fittedActuator canopy lift

Test seat fitted to frameBody work

New drivers seating position now finished Body work

New drivers seat ready to be removed on the mouldBody work

New drivers seat being made in fibre glassBody work

More mounting brackets mocked up Body work

Final actuator mounting brackets made Actuator canopy lift

More top mount plate parts constructedActuator canopy lift

Top actuator curved mount section formedActuator canopy lift

Top actuator mount being mocked up in steelActuator canopy lift

Bottom actuator bracket mocked up in 4mm steel sheetActuator canopy lift

4mm mild steel sheet arrived ready for actuator mount construction

Air vent surround moulded in foam ready for glassingBody work

Front right speaker fitted and modded Bentley right side ventBody work

Actuator brackets fabricated in fibre glass ready to be copied into 4mm thick steel

Actuator mount moulds made to make fabricated metal inserts

Canopy scoop inner detailing done

Canopy actuator mount consturctionActuator canopy lift

Actuator side, internal body mount constuctionActuator canopy lift

2nd actuator canopy bottom mount finishedActuator canopy lift

Foam filled the canopy Body work

Inner actuator boxing being glassedBody work

Dual Actuator mountings being formed into bodyBody work

Electric fuel filler fittings arrived Body work

Reinforced magnetic catch plate fitted Body work

Flush fitting fuel filler door fittedBody work

More body side and top panel detailing

New Bentley fuel filler neck made-Fuel tank

Linear actuator specs added

More side detailing work on body - grinding out star cracks

More bodywork detailing and new boot floor Body work

ABS sensor finished with air gap set at 0.7mm ABS ring

Finished design of reversing gearbox linkage

ABS sensor mount finished

New custom made canopy actuators arrived Actuator canopy lift

Reversing gearbox extension linkage mocked up in woodGearbox reversing

Twin ABS sensors fitted to new mount

Nice chrome front wheel nuts fitted

2nd ABS sensor ordered to mount on new bracket

New ABS sensor bracket madeABS ring

Both sides swage lines and spoiler detailed

Parcel shelf detailedBody work

Head light cowellings detailed

Spun the engine over for the first time - will post a video later

Finished uprated front steering A frame Steering box conversion

Front mods now finishedBody work

New front fresh air scoop fitted

Body mod pictures addedBody work

New fresh air intakes remade in fibre glassBody work

Front indicator recessed lens boxes being made

4 new light pods finished - 2 now molded in

Rear light pods being constructed Body work

Finished engine inspection covers fitted Body work

Head light and bonnet detailing Body work

Steering column recess finished Body work

Engine side access hatches finished

Engine cover recess mounting flange made - DZUS fasteners

2nd engine access cover made Body work

New engine side access cover made Body work

New heater unit being custom boxed in water proofed fiber glass Body work

Body detailing and headlights fixed Body work

More under body repairs and strengthening Body work

Sub woofer cut out finished - old speaker holes filled in

More under body work done

Sub woofer boxed finished and fiber glassed into place Body work

Body repairs and strengthening

Sub woofer box now trimmed Body work

Bonnet fitting for Bond badge support finished Body work

Under body strengthening underway

Fiber glassing sub woofer box for strengthening

Researching new amp for speaker system

New Focal 3 way speaker system arrived Wiring

Sub woofer speaker mounting hole constructed in back of seat

Sub woofer box constructed Body work

Rear spoiler now molded to body

Final rear spoiler out of the mold Body work

New rear spoiler being shaped Body work

New A arm king pin and bearings machined

New Pioneer 10 inch sub woofer arrived

Bonnet repairs finished

Under body mods completed - new bonnet badge cut out made Body work

Canopy locating mount finished Body work

Engine side covers glassed in - pedal box finished

Body off - fiber glassing underneath

Body work inner detailing Body work

Mocking up reversing gearbox lever position

Canopy locating lug finished - more pictures

Foot pedal box fiber glassed in Pedal box

Canopy rear and dash locating lug mounts finished Body work

Quaffer reversing gearbox linkage parts ordered Quaffer reversing gearbox

Inner canopy lug positioned

Air box finished - inner dash completed

New air filter box top made

Split mold completed for air box Air filter

Locating lugs being fitted into central dash board unit and canopy so they mesh exactly when canopy is closed. Body work

Custom air filter box being molded Air filter

New custom sized pedal support frame arrived. Pedal box

New custom made carbon fiber break pipes arrived

Duct box sealed Body work

Inner canopy molding finished Body work

New Air duct molded inlet customized to fit the Bentley dashboard vents

Air intake ducts now molded

Removable side engine covers being mocked up

Pedal box finished

Pedal box gel coated

Revised engine side cover extended

Revised pedal box plywood template fitted

New pedal box plywood template made - new dashboard back plate made Pedal box

Adding engine side cover top ready to take sealing rubber

Dash side now molded around steering column support - added removable side engine cover

Custom badge rubber made - posted to Body work

Added ABS sensor fittings to LSI page

V3 ABS ring finally fitted on prop shaft - time for making the Kaia ABS sensor locating mounts

ABS ring V3 posted - reduced outside diameter and drilled out locating ring

2nd attempt at an ABS ring arrived and fits perfectly over prop shaft locating ring. Pictures posted to LSD page.

Added reversing gearbox extension shaft - machine drawing being prepared for new operating lever

ABS ring back to machinist for central prop shaft location ring drilling

New magnetic lock for rear mesh boot lid arrived

Added chrome hinges and Bentley badge to rear mesh boot lid.

Bought the magnetic catch and boot 'poppers'. Added Classic Mini boot straps.

Remote master cylinders changed - added triple triton reservoirs

Dashboard fiber glassed to canopy inner

Bentley center console fitted

Dash radius wing added and glassed in

Dash now fiber glassed - Bentley grill now recessed

Dash board top being mocked up in bendy plywood

Added 3 new master cylinders and balance bar to foot pedals, chopped out more of the body work to fit new pedal box

Work had come to halt as my fiber glass expert has been ill and I have been working solid for a month.

Work will commence again on the 20th Oct.

New Master cylinder fitted to pedal box

New modified hand brake cables have arrived

New dial mounting plate fitted to steering column

Chopped out body work to fit new pedal box

New pedal box positioning - ordered new custom dial bracket

Wireless paddle and Kaia dial positions mocked up

Final positioning of steering wheel and column

Laser cut ABS new double ring made

Reversing gearbox lever extension tube positioned

Fitted new steering column support - body lowered

Handbrake cables sent off to be modified - drawings added

Body reunited with frame for more trimming

Reversed the Quaffer gearbox into correct direction

EPS-Stopp fitted in final location

Added master cylinder sizes to pedal box

Added top dash side wings - now mocked up in cardboard

Bentley center dash air ducts converted

Centre console frame and back plate made

Steering wheel and column mock up

EPS-Stopp mounting plates fitted

Rear triple fans and relays wired up

Loads more wiring update pictures posted

Air box final fitting

170amp new alternator now wired up

Added new ABS ring to 318 LSD page

New waterproof box added to protect ECU, fuses etc.

EPS-Stopp brackets and fittings being made, line drawings added

Canopy - existing lock now filled in. Roof and drainage channel detailed

Added magnetic canopy lock - housing now made

Added Bentley center console framework mounting

Added EPS-Stopp layout pictures

Canopy door hinge mounting plates finished.

Added Carter Wireless Control flippy paddles

Flat shifter and steering wheel - paddle operated gears

Canopy air spoiler now bonded to canopy

Bearings fitted to steering shaft and loosely located in position on the Bug

Kawasaki ancillary wiring extended - pictures

Loosely plugged in the Kaia wiring loom to the engine - wiring up ancillary's

Added two new potential 2 pedal brake and clutch balanced bar set ups

MGTF swinging arms and disc brakes- foot pedals

Both of old rusty canopy side tubes have been cut out and replaced

Added Engine connections tab - trying to connect up all the pipes prior to starting

New UTO-VOX V5PRO OEM Mirror Dash cam added to wiring - cables now routed through fiber glass canopy.

Fiber optic head-lining lights power unit recessed into canopy

Alternator housing is now finished - latest pictures of black anodized finish

170 amp new external alternator

Bentley dash board button printed circuit boards sent of for redesign.

Dash board - Bentley Continental GT

New steering column splined shaft conversion made. New 'Lite' custom made bearings have arrived

The links below that are active and have been uploaded

External air scoop mold made and fiber glassed for finished scoop

Scoop now taken out of mold and now glassed into final position

More shaping pictures added to internal air duct to accommodate canopy rubber seal

Test D profile canopy seal fitted

Added custom made steel boot lid with mesh insert to bodywork page

Send me a mail for comments and any tips you have to christening@interconnection

Custom triple fan cooling and fuel tank

Dash board - Bentley Continental GT

Engine extractor manifold and exhaust system

E- St opp electric hand brake - current project

Flat shifter and steering wheel - paddle operated gears

MGTF swinging arms and disc brakes- foot pedals

Quaffer to chain converter - Quaff to BMW prop shaft

170 amp new external alternator

Modified to take independent rear suspension through a limited slip differential

Original fixed axle and frame set up before conversion